Zhejiang Haitong | How to move from "Made in China" to "Intelligent Manufacturing in China"?

Published Time:

2022-12-15 10:44

Source:

Haitong is committed to building a world-class Chinese brand, rooted in quality, core in innovation, and key in reputation. Haitong's brand confidence stems from its quality confidence.

Characteristics of Intelligent Manufacturing

Intelligent manufacturing is the core of the new industrial revolution. It's not about further improving the efficiency and precision of equipment, but about using equipment more rationally and intelligently, maximizing the value of manufacturing through intelligent maintenance; it focuses on the production field, but it is also an end-to-end transformation process that will drastically change the entire ecosystem, including R&D, production, products, channels, sales, and customer management. For industrial enterprises, on the production and factory side, it can still be based on scale, standardization, and automation, but it also needs to be endowed with new characteristics of flexibility, customization, visualization, and low carbon; on the business model side, there will be disruptive changes—the model in which producers influence consumers will be replaced by the model in which consumer demand determines product production; at the national level, it is necessary to establish an industrial Internet that is more secure and reliable than the consumer Internet.

As a broad concept, intelligent manufacturing includes five aspects: product intelligence, equipment intelligence, intelligent production methods, intelligent management, and intelligent services.

1. Product Intelligence

Product intelligence involves integrating sensors, processors, storage devices, communication modules, and transmission systems into various products, enabling products to have dynamic storage, perception, and communication capabilities, and making products traceable, identifiable, and locatable. Computers, smartphones, smart TVs, robots, and smart wearables are all "natives" of the Internet of Things (IoT). These products are network terminals from the moment they are produced. Traditional air conditioners, refrigerators, automobiles, and machine tools are "immigrants" to the IoT. In the future, these products will also need to be connected to the network world. Experts estimate that by 2020, the number of these IoT "natives" and "immigrants" will exceed 50 billion, and this process will continue for 10, 20, or even 50 years.

2. Equipment Intelligence

Through the integration and fusion of advanced manufacturing, information processing, and artificial intelligence technologies, intelligent production systems with self-organizing and self-adaptive functions such as perception, analysis, reasoning, decision-making, execution, and autonomous learning and maintenance, as well as networked and collaborative production facilities, can be formed. These all belong to intelligent equipment. In the era of Industry 4.0, the process of equipment intelligence can proceed in two dimensions: single-machine intelligence, and the interconnection of single machines to form intelligent production lines, intelligent workshops, and intelligent factories. It needs to be emphasized that simply transforming R&D and production is not the whole of intelligent manufacturing. Front-end transformation based on channel and consumer insights is also an important part. The two must be combined and complement each other to complete the end-to-end intelligent manufacturing transformation of the entire chain.

3. Intelligent Production Methods

New formats and models such as personalized customization, ultra-small-batch production, service-oriented manufacturing, and cloud manufacturing essentially reorganize the relationships between customers, suppliers, sales agents, and internal organizations of enterprises, restructure the operation modes of information flow, product flow, and capital flow in the production system, and rebuild new industrial value chains, ecosystems, and competitive landscapes. In the industrial age, product value was defined by enterprises. Enterprises produced what products, users bought what products, and enterprises set prices, users spent money—the initiative was completely in the hands of enterprises. However, intelligent manufacturing can achieve personalized customization, not only eliminating intermediate links but also accelerating commercial flow. Product value is no longer defined by the enterprise but by the user—only products that users approve of, participate in, are willing to share, and don't speak ill of, have market value.

4. Intelligent Management

With the continuous deepening of vertical integration, horizontal integration, and end-to-end integration, the timeliness, completeness, and accuracy of enterprise data are constantly improving, which will inevitably make management more accurate, efficient, and scientific. Haitong is using a mature intelligent management system. It has interconnected internal office, management, client, production, and warehousing and logistics ends, with integrated intelligent management. Customers can directly place orders and purchase through Haitong's online channels, and the online intelligent ordering, order placement, production, and delivery system can complete transactions independently.

5. Intelligent Service

Intelligent service is the core content of intelligent manufacturing. More and more manufacturing enterprises have realized the importance of transforming from production manufacturing to production service manufacturing. In the future, O2O services that run in parallel online and offline will be realized. Two forces are moving toward each other in terms of service intelligence. One force is the continuous expansion of services by traditional manufacturing enterprises, while the other force is the entry of consumer Internet into industrial Internet, such as WeChat, which will connect not only people in the future, but also equipment and equipment, services and services, and people and services. New services such as personalized R&D design, general integration, and general contracting Product life cycle management will constantly emerge with the changes in production methods.

Future Direction: Haitong Intelligent Manufacturing

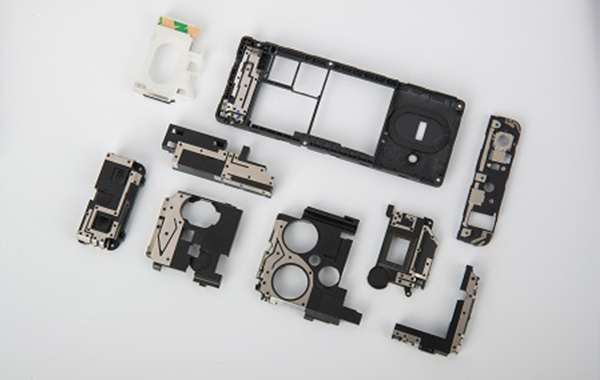

Zhejiang Haitong Communication Electronics Co., Ltd. began deploying intelligent manufacturing as early as 2015, comprehensively solving the problems of integrated, large-scale, and standardized production. As a leading international provider and manufacturer of solutions for communication electronics industry product accessories, Haitong has always placed product quality as its core. At the beginning of the emergence of big data, AI, and artificial intelligence, the company was already thinking about and trying to use these cutting-edge technologies to improve product quality.

Haitong's Confidence in Quality Creates Brand Confidence

Using Chinese brands to tell Chinese stories, quality is the cornerstone. "Quality First" and "Strong Nation Through Quality" require enterprises to cultivate and promote the spirit of "striving for excellence" according to international first-class quality standards. Zhejiang Haitong meets market demands with high-quality standards, leads brand upgrading through quality, and uses quality confidence to achieve brand confidence.

Haitong's brand confidence stems from its products. Traditional manufacturing enterprises should take consumer needs as their center, develop new products, apply new technologies, and expand new models by integrating intelligent manufacturing and industrial Internet. Haitong is accelerating its transformation into a digital technology company, constantly improving product and service levels, and optimizing the consumer experience. Brand confidence comes from high circulation. High-quality and efficient products must be supported by a good circulation system. We must embrace the world and cover all channels. Only by giving products greater value, higher cost-effectiveness, and meeting diversified needs can we win the capital for sustainable brand development.

In recent years, Haitong has shifted from "Made in China" to "Intelligent Manufacturing in China," striving for high-quality development and achieving a high level of integration between culture and brand. For Zhejiang Haitong, the value foundation of the brand lies in down-to-earth accumulation, and the brand's self-confidence stems from long-term perseverance. Therefore, in recent years, the company's business focus has been on quality, customer service, and intelligent manufacturing, striving to create high-quality, reliable, and demand-satisfying products.

Previous Page

Related News

Haitong Communications | What is 5G-A?

At the recently concluded 2024 Mobile World Congress, a new technology took center stage: 5G-A. What exactly is this technology, and how will its emergence change our lives? Let's delve into the mysteries of 5G-A.

Haitong Communications | So many antennas are running on a 5G phone

Mobile phone design is a holistic endeavor. To achieve faster and smoother communication performance, the overall design will undergo significant changes, starting with the antenna.

Haitong Communication | Excellent Connector Project Express Delivery

Introduction to Haitong Communication Connectors: Haitong Communication can independently design and manufacture high-quality RJ connector products that meet FCC-part68, IEEE802.3, and ANSIX3.263 standards. Haitong currently has integrated RJ products with filtering functions and RJ products without filtering functions. Haitong's RJ products support network applications of different speeds, the most common of which are: 10/100base-T, 1000base-T, 2.5G/5Gbase-T, 10Gbase-T. Some types of RJ products can simultaneously have

Haitong Communications | The Evolution of Mobile Phone Antennas

The mobile phone antenna is an important component of mobile phone communication. The earliest mobile phone antennas can be traced back to the early 1980s, and their development has gone through several stages.

Haitong Communication | Excellent FPC Antenna Project Express Delivery

FPC Antenna: 1. FPC generally refers to a flexible printed circuit board, which is made of polyimide or polyester film as a substrate and has high reliability and excellent flexibility. It is lightweight, thin, flexible, foldable, high-performance, and low-cost. Compared to other PCB antennas, ceramic antennas, and LDS antennas, FPC antennas offer higher cost-effectiveness.

Zhejiang Haitong Communications | Women's Day Charm on March 8th

Haitong Goddess Festival Activities

Haitong Communication's In-Vehicle IoT Solution for T-BOX Systems

Haitong Communication has launched a constantly improving and reliable in-vehicle T-BOX accessory solution in the fields of antennas, metal parts, communication interconnection interfaces, and plastic shells.

©2024 Zhejiang Haitong Communication Electronics Co., Ltd. www.300.cn SEO